Battery Recycling Solutions

-

- Batteries

-

- Batteries

How We Do It

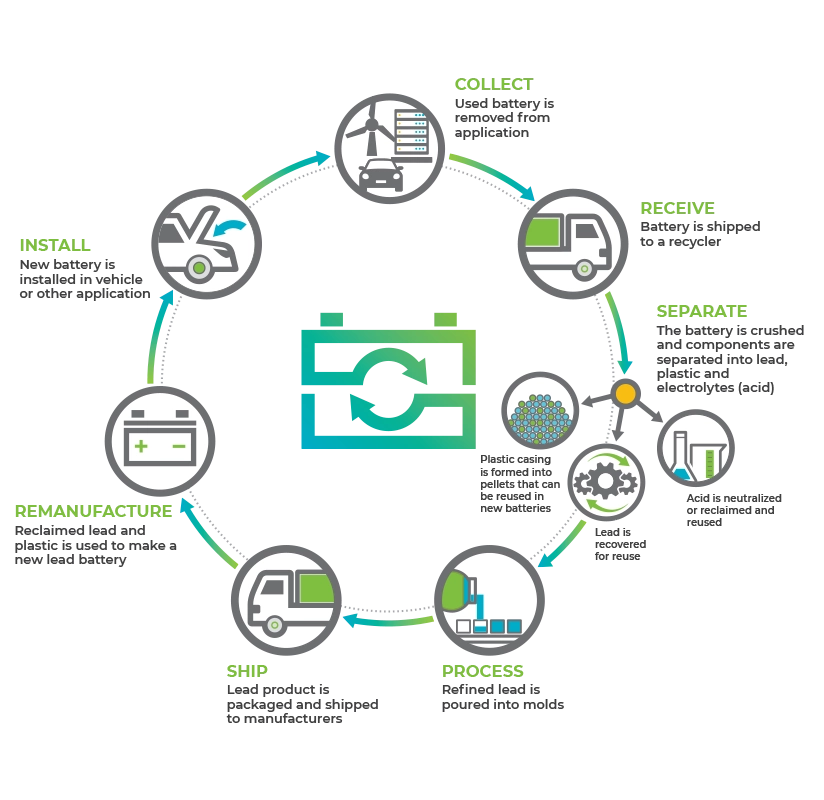

We continually strive to find new ways to recover and upgrade the constituent components of end-of-life batteries to create value for our customers and society. We partner with major North American battery manufacturers to provide a sustainable closed-loop, circular-economy solution to capture spent batteries and recover their valuable components locally for reuse. In doing so, we help achieve a 99 percent recycling rate – the highest of any consumer product in North America. This helps conserve natural resources and protect the environment.

Lead from batteries can be infinitely recycled. The process starts by feeding used batteries into a machine that breaks them down. From there they are separated into their constituent components of lead, plastic and acid.

The lead is melted, purified, refined into specific customer-driven formulas and cast into lead ingots and blocks. It is then returned predominantly back to battery manufacturers, who use it to manufacture new batteries, closing the loop of the circular economy for lead batteries.

The plastics are separated, cleaned and processed into chips. From there, they are upgraded into high-quality polypropylene pellets that are reused in the making of new battery casings and other products.

The acid is collected and reused in many industries, reducing the need for virgin chemicals.

To learn more about the lead battery recycling process – the quintessential example of a circular economy – watch this video from Battery Council International.